Introduction: At Custom Resin Solutions, we have developed a next-generation 3D-printed composite resin that revolutionizes permanent dental restorations. Engineered for exceptional flexural strength, superior dimensional stability, long-term durability under occlusal stress, and proven biocompatibility, CRS Composite resin outperforms conventional alternatives and bridges the gap between digital efficiency and clinical excellence.

In clinical dentistry, the mechanical performance of restorative dental materials is a key determinant of long-term treatment success. Among mechanical properties, flexural strength is critical for permanent restorations such as crowns and bridges, which must endure repeated chewing forces over years of use since the mandibular movement exerts forces on upper and lower teeth, so flexural strength properties play an important role in dentistry. Permanent restorative resins are considered mechanically integrity-worthy because their structural properties are highly functionally relevant [1]. Considering that long-term restorative materials enhance implant lifespan and affect case success outcomes, the quality of the material's mechanical properties becomes a significant factor [2].

Polymer-based crown and veneer materials must be able to stand at least 50 MPa, according to ISO 10477 [3]. In practice, higher thresholds are often recommended for load-bearing restorations.

Three-point flexure tests are recommended by the International Standards Organization for determining flexural strength by loading bar-shaped specimens with an edge indenter and applying force in the middle of the specimen to determine the strength elasticity value.

Understanding Flexural Strength

Flexural strength, also known as bending strength, refers to the maximum stress a material can withstand before breaking when subjected to bending. Flexural strength is a key performance indicator for permanent restorative resins, especially in dental applications where restorations must endure continuous occlusal stress. Defined as the maximum stress a material can withstand before fracturing under bending forces, flexural strength is essential for ensuring the durability and long-term function of 3D-printed dental materials.

In clinical dentistry, long-term restorative polymers used in crown and bridge applications are exposed to repeated chewing forces, making their flexural strength a direct predictor of success. Measured via three-point bending tests, flexural strength value indicates a material’s ability to resist crack formation and failure during function.

The included studies measured flexural strength using the three-point bending test, as illustrated in Figure 1.

.png)

Figure 1: Illustration of the three-point bending test

High flexural strength indicates that the material can better resist bending forces, reducing fracture risk under occlusal loads. This is particularly critical for permanent restorations that must endure long-term stress. Materials with superior flexural strength tend to have improved resistance to cyclic loading, which is a common challenge in the oral environment.

Clinical Importance of Flexural Strength in Permanent Restorations

Photopolymer restorative resins are intended for short-term and long-term restorations. They must still withstand masticatory forces, temperature variations, and chemical exposure and must endure the repeated mechanical stresses of mastication over years so flexural strength is one of the most important mechanical properties of dental restorative materials [4]. This property is directly related to a restoration’s ability to withstand occlusal loads – the biting and chewing forces exerted in the mouth. During mastication, significant bending stresses occur, and a restoration must resist these forces without fracturing [5]. In clinical terms, flexural strength is a key predictor of how a material will perform under continuous masticatory pressure over time. Materials with higher flexural strength endure repetitive stress better: The posterior regions, where forces are highest, are less likely to crack or deform when a patient bites down. A resin with low flexural strength, on the other hand, may bend or crack under normal chewing loads over time, resulting in premature failure.

Longevity of a permanent restoration is closely tied to its flexural strength. A restoration must withstand thousands of chewing cycles daily; insufficient flexural strength can result in the initiation and propagation of cracks under these cyclic loads. The micro-fractures in the restoration may eventually compromise its integrity and cause catastrophic failures. According to studies, resins with a higher flexural strength are better able to resist deformation and fracture under continuous chewing forces, which is crucial for the long-term integrity of crowns and bridges [6].

The Advantages of Selecting Restoration Resins with High Flexural Strength

A permanent 3D printing resins that exceeds the minimum flexural strength has several clinical advantages. A high flexural strength not only meets the basic standard, but provides a buffer of safety that improves performance and reliability. Key clinical benefits of high flexural strength are as follows:

While flexural strength is a critical mechanical property in evaluating 3D printed dental resins, it is not the only factor influencing clinical performance. Other key properties, such as fracture toughness, elastic modulus, and fatigue resistance also play an essential role in determining a restoration’s long-term success.

However, consistently high flexural strength remains one of the most reliable predictors of a material’s ability to withstand functional load and resist mechanical degradation over time. In the context of permanent 3D printed restorative materials, elevated flexural strength often correlates with greater durability, fewer failures, and improved overall treatment outcomes [6].

Method

In this study, all materials subjected to mechanical testing have been prepared based on the manufacturer's recommended instructions for use documents. For testing purposes, a total of six samples were prepared from resins developed by three different manufacturers for permanent dental restorations. The samples were evaluated using a three-point flexural test with a Zwick Z250 universal testing machine (ZwickRoell, Yokohama, Japan). The applied load speed was set at 5 mm/min, and the results represent below. The equivalent alternative brand resins, developed for the same purpose, are listed below with only the first letter of the manufacturer's name and the country of manufacture.

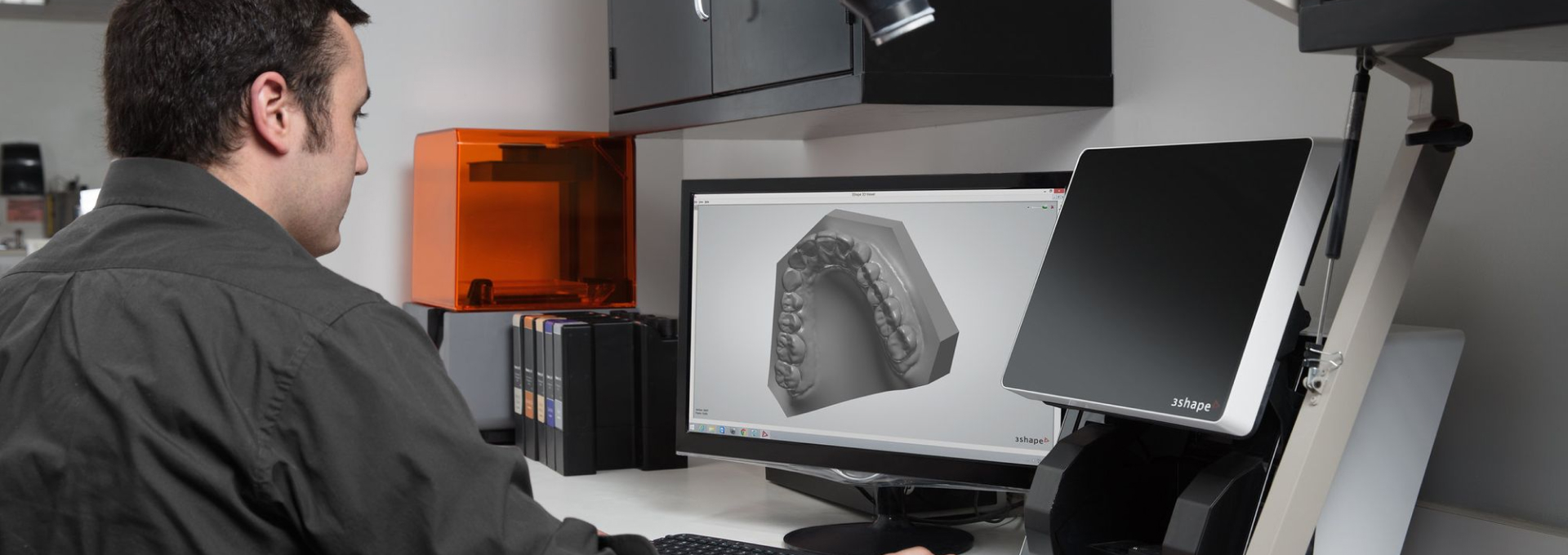

Table 1: Three-Point Bending Test Results of the samples coded "A"

|

Sample Number |

Flexural Modulus (GPa) |

Flexural Strength (MPa) |

|

A1 |

3.2 |

68.7 |

|

A2 |

3 |

69.8 |

|

A3 |

3.1 |

77.6 |

|

A4 |

3.3 |

77.4 |

|

A5 |

3.3 |

68.7 |

|

A6 |

2.9 |

71.1 |

|

Mean Value |

3.1 |

72.2 |

Figure 2: Three-Point Bending Test Graphs of the samples coded "A"

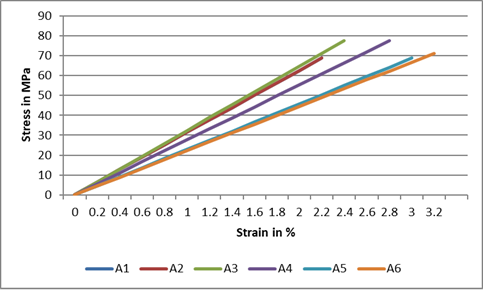

Table 2: Three-Point Bending Test Graphs of the samples coded "B"

|

Sample Number |

Flexural Modulus (GPa) |

Flexural Strength (MPa) |

|

B1 |

3.9 |

126.1 |

|

B2 |

3 |

104.1 |

|

B3 |

2.7 |

111.1 |

|

B4 |

4.1 |

128.6 |

|

B5 |

3 |

104.1 |

|

B6 |

3.9 |

119 |

|

Mean Value |

3.4 |

115.5 |

Figure 3: Three-Point Bending Test Graphs of the samples coded "B"

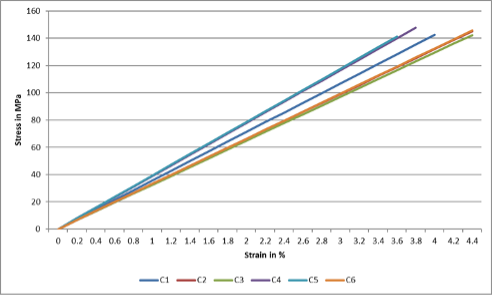

Table 3: Three-Point Bending Test Results of the Custom Resin Solutions Composite Resin

|

Sample Number |

Flexural Modulus (GPa) |

Flexural Strength (MPa) |

|

C1 |

3.6 |

142.4 |

|

C2 |

3.7 |

145.2 |

|

C3 |

3.6 |

142.3 |

|

C4 |

3.7 |

147.7 |

|

C5 |

3.6 |

141.1 |

|

C6 |

3.7 |

145.6 |

|

Mean Value |

3.6 |

144.05 |

Figure 4: Three-Point Bending Test Graphs of the Custom Resin Solutions Composite Resin

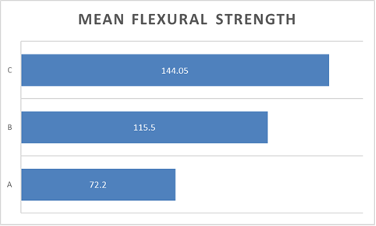

Figure 5: Average Flexural Strength Values of Tested Resins

Among the three 3D-printed restorative resins tested, the CRS (Custom Resin Solutions) resin achieved the highest flexural strength (144.05 MPa). It is evident that the material offers greater flexural strength than alternative materials in terms of mechanical performance. From a scientific and clinical perspective crowns or bridges made with CRS Composite resin should be able to tolerate occlusal loads with a greater margin of safety, resulting in a lower fracture risk.

The superior flexural strength of CRS Composite resin carries several clinical implications:

Conclusion

The findings of this study confirm that flexural strength is a critical mechanical parameter in the success of 3D-printed dental restorations. Among the materials tested, the composite resin developed by Custom Resin Solutions exhibited the highest average flexural strength at 144.05 MPa. This positions the CRS Composite resin favorably compared to other commercially available alternatives included in the study.

Such a high level of flexural strength has been observed to provide improved resistance to functional stresses, particularly in load-bearing restorations such as posterior crowns and bridges. While all tested materials met the minimum clinically acceptable threshold, the CRS Composite resin appears to offer a broader safety margin under repeated occlusal loading.

In addition, since receiving its CE certification under the MDR framework in August 2023, the CRS Composite resin has been actively used and monitored in clinical cases both domestically and internationally. Observations and feedback from these cases have been consistent with the laboratory data, supporting the material’s high flexural strength performance.

To sum up, these findings indicate that the CRS resin offers high mechanical reliability and long-term clinical stability in relevant applications. Further long-term in vivo studies would be valuable to fully assess the clinical impact of these results.

Reference

1 Amin, F., Farhan, T., Kumar, N., & Mahmood, S. J. (2020). Exploration of the Customized Fixtures for the Evaluation of Three-point Bending Strength of Dental Resin Composites. 9(1), 51–55. https://doi.org/10.22038/JDMT.2020.44057.1320.

2 Rauch, A., Heinzmann, W., Rosentritt, M., Hahnel, S., Schmidt, M. B., Fuchs, F., & Koenig, A. (2023). Aging and Fracture Resistance of Implant-Supported Molar Crowns with a CAD/CAM Resin Composite Veneer Structure. Journal of Clinical Medicine, 12(18), 5997. https://doi.org/10.3390/jcm12185997.

3 The International Organisation for Standardization. ISO 10477:2020 Dentistry — Polymer-based crown and veneering materials, https://www.iso.org/standard/80007.html, 2025.

4 View of Characterization of temporary and permanent 3D-printed crown and bridge resins Biomaterial Investigations in Dentistry. (n.d.). https://doi.org/10.2340/biid.v12.43584.

5 Basheer, R. R., Hasanain, F. A., & Abuelenain, D. A. (2024). Evaluating flexure properties, hardness, roughness and microleakage of high-strength injectable dental composite: an in vitro study. BMC Oral Health, 24(1). https://doi.org/10.1186/s12903-024-04333-3.

6 Banerjee, S., Jha, S., Singh, R., Shahi, H., Arya, A., & Raj, R. (2024). Flexural Strength of Different Commercially Available Auto-Polymerizing Acrylic Resins: An In Vitro Study. Cureus, 16(10), e71905. https://doi.org/10.7759/cureus.71905.