Our success is shaped by our global linguistic diversity. We work with multicultural individuals who are fluent in multiple languages and can seamlessly integrate into our worldwide operations.

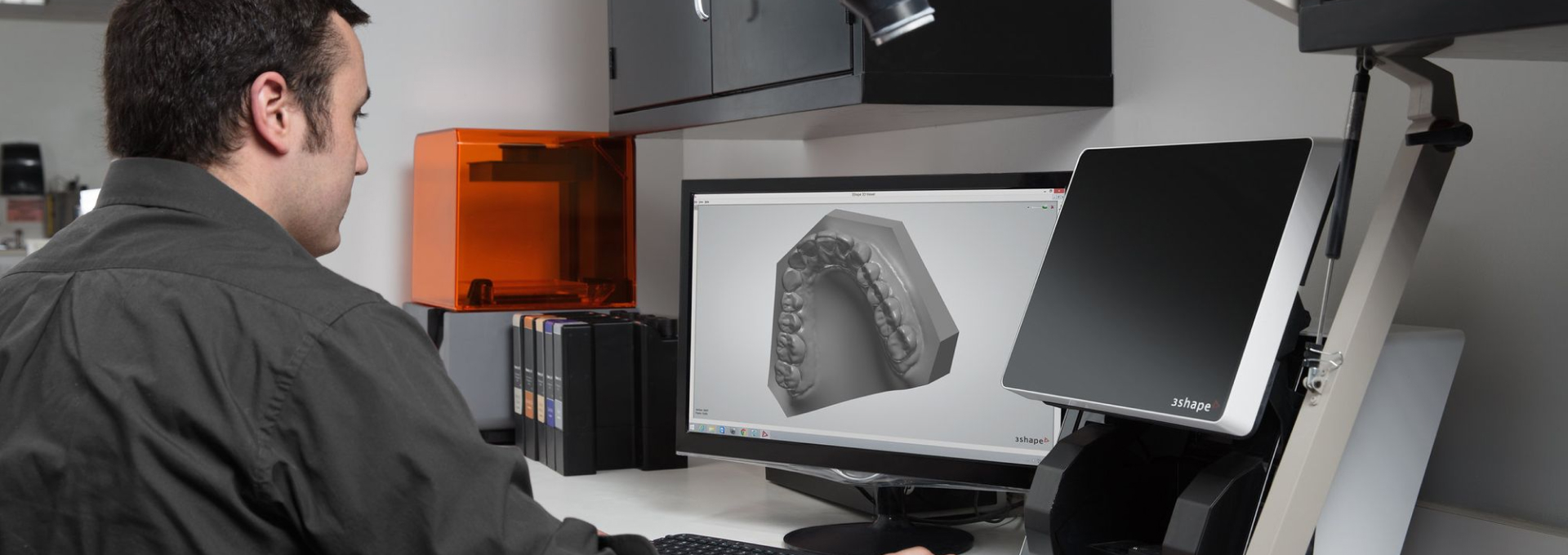

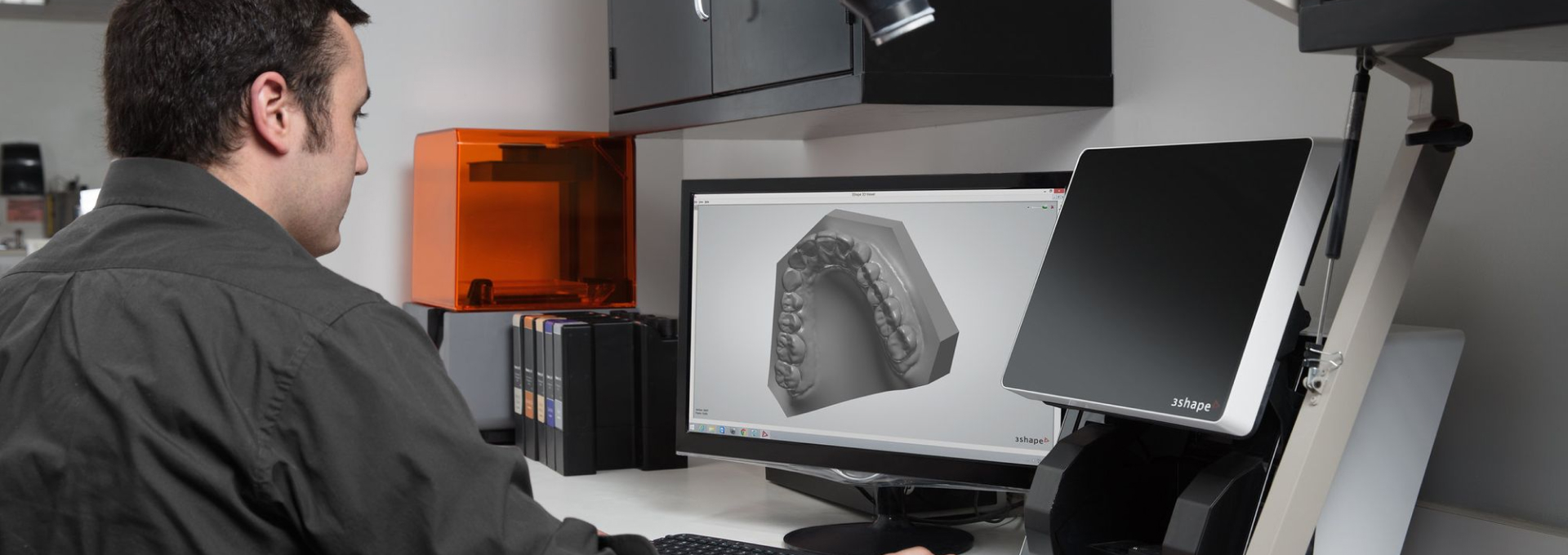

Dental model production is essential in modern dentistry and requires high precision, repeatability, and reliable fit for downstream prosthetic work. Plaster (gypsum) models have long been the gold standard, but digital dentistry and photopolymer resins now enable faster production, improved reproducibility, and more predictable dimensional stability.

This white paper reviews key advantages and practical considerations of Custom Dental Model Resin by comparing 3D-printed models with traditional plaster models and commonly used commercial model resins.

Plaster models remain widely used thanks to decades of clinical familiarity and low material cost. However, gypsum workflows can involve higher material waste, longer production times, and potential accuracy variability. Over time, plaster models may also be affected by environmental humidity, which can reduce dimensional stability and impact precise prosthetic fit. (Lümkemann et al., 2023)

Custom Dental Model Resin is designed to address common limitations of traditional model workflows. A key advantage of resin-based model production is process standardization: consistent raw material control and manufacturing parameters can support repeatable output from batch to batch.

| Criteria | Plaster Models | Custom Dental Model Resin (3D-Printed Models) |

|---|---|---|

| Dimensional stability over time | Generally stable, but may change with moisture exposure. | Minor changes can occur depending on geometry; dentate models may remain more stable than edentulous models over time. (Zarbah et al., 2024) |

| Material behavior | Moisture interaction may contribute to dimensional changes. | Photopolymer resins are typically more moisture resistant, supporting dimensional stability. (Zarbah et al., 2024) |

| Flexural strength | Lower strength range, more prone to chipping/cracking in handling. | Higher durability; reported flexural strength around 60 MPa for printed model resin categories in literature. (Lümkemann et al., 2023) |

| Accuracy / trueness | Can vary with mixing, setting, and storage conditions. | High precision with low shrinkage potential; supports better-fitting prosthetics in digital workflows. (Lümkemann et al., 2023) |

| Deformation factors | Humidity and storage conditions can influence stability. | Small long-term changes may occur depending on design; dentate models may be more stable than edentulous models. (Zarbah et al., 2024) |

| Production time | Slower, manual steps may extend turnaround time. | Faster production; multiple models can be printed simultaneously. (Lümkemann et al., 2023) |

| Material consumption | Higher material usage per model (varies by workflow). | Often lower material use per model, reducing waste (depends on print design and supports). |

| Storage effects | More sensitive to humidity and handling damage. | More resistant to environmental conditions in many use cases. (Zarbah et al., 2024) |

| Surface detail | Initially detailed; can degrade with wear/transport. | High detail reproduction supports clear margin evaluation. (Zarbah et al., 2024) |

| Reproducibility | New physical impression/cast may be needed per remake. | Repeatable reproduction from STL files without new impressions. (Zarbah et al., 2024) |

| Clinical workflow fit | Common and familiar, but storage and transport can introduce errors. | Well-suited for complex digital restorations and implant prosthetics with consistent output. (Zarbah et al., 2024) |

| Cost efficiency | Lower upfront cost; recurring labor/time costs may be higher. | Higher upfront investment (printer ecosystem) with long-term savings potential via digital workflow and reduced waste. |

Figure 1: Left: Custom Model Resin. Right: Other well-known commercial resins.

Figure 2: Left: Custom Model Resin. Right: Other well-known commercial resins.

Figure 3: Left: Custom Model Resin. Right: Other well-known commercial resins.

Figure 4: Left: Custom Model Resin. Right: Other well-known commercial resins.

The comparative findings indicate that resin-based model production can improve workflow efficiency, reproducibility, and handling durability in many dental laboratory scenarios. Custom Dental Model Resin supports digital workflows through consistent output, strong surface detail visibility, and practical advantages such as easier cleaning and reduced post-processing time.

For labs adopting digital dentistry workflows, printed models can help deliver more predictable fit and faster turnaround, while maintaining high detail resolution for technician evaluation. Overall, Custom Dental Model Resin is positioned as a reliable option for modern dental model production where accuracy, efficiency, and repeatability are priorities.

Learn more about our dental 3D printing resin solutions designed for accuracy, safety, and regulatory compliance.

#DentalResins #DentalModelResin #DentalModelPrinting #3DPrintedDentalModels #Dental3DPrinting #DigitalDentistry #DentalLab #DentalLaboratory #DentalWorkflow #CADCAMDentistry #IntraoralScanner #STLWorkflow #ModelResin #PhotopolymerResin #LCD3DPrinting #Resin3DPrinting #DimensionalAccuracy #DimensionalStability #TruenessAndPrecision #MarginLineDetail #LowShrinkage #FlexuralStrength #GypsumModel #PlasterModel #DentalCast #ImplantAnalog #ImplantProsthetics #CrownAndBridgeWorkflow #Prosthodontics #OrthodonticsLab #RemovableProsthetics #DentalTechnician #CostEfficiency #SustainableDentistry #CustomResinSolutions